Why led lamps need pay attention to heat dissipation? Traditional lamp don’t need that?

1:Why led lamps need pay attention to heat dissipation? Traditional lamp don’t need that?

- CFL,lighting by heat, and it doesn’t matter if the temperature isn’t hot enough to melt the glass;

- Halogen light is hot, but it doesn’t have any effect on efficiency and life. It doesn’t matter if it’s not hot enough to melt the parts;

- The temperature of the metal halide lamp tube is very high, unless the high power generally does not need to pay too much attention to the heat dissipation.

“ This is a high-power metal halide lamp, if the heat is not good, may lead to the melting of the electrode, so he has a very thick electrical connector, and some will be in the water, heat dissipation.”

2:Why LED afraid of heat?

Whenever how many watts for led lamps, because its afraid heat so result must do heat dissipation. LED is a semiconductor device, the high temperature will shorten the life, performance decline, and over.

When led chip works, it heats up. We call the PN junction temperature as junction temperature.

What LED really does is a small piece of chip.

3: What is the relationship between junction temperature and LED luminous flux?

“The higher the junction temperature result the smaller the luminous flux , and the higher the junction temperature will result the LED working state will be drop.”

4: What is the relationship between junction temperature and LED life? (general luminous flux dropped to 70% when we think LED over.)

“The junction temperature of 105 degrees, the flux decreased rapidly to 70%, then the LED lamp life is about 10 thousand hours, if the control temperature to 55 degrees, LED life can be up to 100 thousand + hours.”

So, we have to find a way to cool down and let LED dissipate the heat that you have.

5: So, how do you get rid of the heat?

- LED Heat dissipation principle: The heat dissipation to 3 modes: conduction, convection and radiation.

a: Conduction: the way of heat from the higher part of the object along the body to the lower part of the temperature;

Factors affecting heat transfer:

1. heat sink material

2. heat dissipation structure;

The closer the material sticks, the faster the heat transfer, and if the two materials only touch a little bit, the heat conduction will be blocked, and this is the thermal resistance. At this point, we can heat the material between the materials so that the heat passes well.

3. Shape and size of heat conducting material.

2. Radiation: the phenomenon that high temperature objects radiate outward directly:

The efficiency of thermal radiation depends on the thermal resistance of the surrounding medium (the surrounding media is often referred to as air) and the characteristics of the thermal radiation itself. But the radiation heat transfer is not so important for the LED lamp, the lamp itself because the temperature is not high, when the temperature is not too high, the phenomenon of radiation is not very strong, so this method considers when the heat dissipation is less.

3. Convection: the removal of heat by the flow of gas or liquid.

“The heat goes up from below, and back to cooler things.”

Now there are two radiators, almost the same shape, but one is sealed, one opened the slot, it is obvious that the right side radiator cooling capacity is much better, it in addition to conduction heat dissipation and convection, and left to rely on conduction to dissipate heat.

Understand the relationship between heat dissipation and lamp luminous efficiency, life, and the way of heat dissipation, what is the way to judge whether a lamp is good or bad?

6. How to judge whether a LED lamp is good or bad?

A reasonable design of heat dissipation, make fine lamps, heat dissipation capacity and power corresponding correspondence. The volume and weight of the heat sink determine the storage capacity of the heat, so the heat sink always has a big size. The area of the heat sink determines the final emission capacity, in order to increase the area, usually made a variety of columns, mesh, film and other shapes.

A reasonable design of heat dissipation, make fine lamps, heat dissipation capacity and power corresponding correspondence. The volume and weight of the heat sink determine the storage capacity of the heat, so the heat sink always has a big size. The area of the heat sink determines the final emission capacity, in order to increase the area, usually made a variety of columns, mesh, film and other shapes.

Heat sink make up a big chunk of the cost of light fixtures. Some factories for save cost, save materials . So, here’s the question: how do we judge whether a heat sink for a lamp works well?

Of course, directly method is test working LED chip junction temperature. Whenever, the temperature control is within the acceptable range, that is to do well, otherwise, it is cutting corners.

7. How to test?

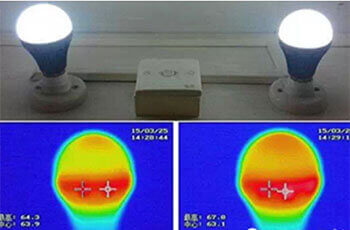

1: Infrared thermal imager is a common non-contact temperature measuring equipment.

Using professional imagers, only external temperature can be seen, and chip temperature at the core can not be known.’

But general speaking, somebody will choose used hand touch test lamps temperature, it is ok?

Frist , Hand touch test LED lamp temperature, itself does not have discipline theory, after all, different people perceive temperature sensitivity is different. However, when the test equipment is not in the field, hand touch can also roughly judge the temperature of the lamp, the premise is that the lamp temperature is lower than the use of the temperature of the burned hand.

But touch the head sink is not hot, not necessarily good.

When the LED lamp works normally, a good head sink must have a lower temperature, but the heat sink with lower temperature is not necessarily good.

The chip has few heat, good conduction, enough heat dissipation and low handle temperature. This is a good cooling system, and the only “drawback” may be a waste of materials.

So why is the heat sink that feels low in temperature not necessarily a good ? The problem is mainly in the conduction of heat, when the heat generated by the heat can not be smoothly transported to the scattered piece, the heat accumulation in the vicinity of the heat source, heat transfer to the heat sink by high temperature difference, so the handle temperature is not high.

If there are impurities under the PCB board, there is no good contact with the heat sink, the heat can not spread out, concentrated in the chip. It’s not hot outside, in fact, the chips are already hot!

Touching the heat sink is very hot. It must be bad.

If touch the heat sink is very hot, the cooling system is certainly not good, or heat sink cooling capacity is insufficient, there may be either the Mavericks pull carts; the effective heat dissipation area is not enough, the heat can not be quickly with ambient air for heat exchange, cause lamp with air temperature difference in heat dissipation, so feel very hot.

Heat sink volume or area is insufficient, the heat of the chip can not be sent out in time, it will cause touch is very hot.

Some heat sink look very thick, but the “effective heat dissipation area” is not enough. A set of cooling systems, in which part of the heat sink area can be fully exposed to ambient air and the air can quickly leave freely, can be called “effective heat dissipation area””. Other materials that can not be free and full contact area of the air, at best, can only be heat capacity materials or heat radiation area.

So how to systematically identify the heat dissipation of LED lamps?

“Half hour illuminance method” to measure junction temperature”

Since we can’t measure the junction temperature directly, is there an indirect way to know the junction temperature? Fortunately, when the LED junction temperature rises, the luminous flux will decrease. Then, as long as we measure the illuminance change of the lamp at the same position, we can reverse the change of junction temperature.

7. HOW?

1, choose a place that is not disturbed by the outside light, preferably at night, turn off other lights.

2, cold light, immediately measure a position of illumination, record the reading at this time is “cold state illuminance””.

3, Keep the position of lamps and illuminance unchanged, lamps work continuously.

4, half an hour later, read the illuminance value here, record the reading is “hot state illuminance”

5, if the difference between the two values (10~15%), the cooling system of the lamp is basically good.

6, if the two values are very different (greater than 20%), the heat dissipation system of this lamp is doubtful.

Indirect measurement of junction temperature change by half hour illuminance method.

From the curve of luminous flux vs junction temperature, it can be seen from this curve that the luminous flux decreases by how many lumens, and it can be indirectly learned that the junction temperature rises to how many degrees celsius.

When OSRAM S5(3030)Chip the luminous flux decreases by 20% at 25℃, the junction temperature is over 120 centigrade.

When OSRAM S8(5050)Chip the luminous flux decreases by 20% at 25℃, the junction temperature is over 120 centigrade.

When OSRAM E5(5630)Chip the luminous flux decreases by 20% at 25℃, the junction temperature is over 140 centigrade.

So we can know, If the thermal illuminance after half an hour is 20% lower than that in the cold state, the junction temperature is basically above the tolerance range of the chip. It can basically judge that the heat dissipation system is unqualified.

Is there a special case? Of course, at the end of this article, take a counterexample,

OSLON Square 1-5W The chip junction temperature increases from 25℃ to 40 ℃, the flux is Nitian rising! Then it began to decline, and the luminous flux decreased by about 10% at 120℃. So, for this chip, with half hour illumination method to assess the heat dissipation, only accept the change of 5~8%!